|

Long slender filaments or fibers suspended in fluids are

fundamental to understanding many flows arising in physics, biology

and engineering. Examples include fiber-reinforced composites, the

dynamics and rheology of biological polymers and the motility of

microscopic organisms.

Such filaments often have aspect ratios of length to radius

ranging from a few hundred to several thousand. Full

discretizations of such thin objects in a 3D domain is very costly.

By applying a non-local slender body theory, an integral equation

along the filament centerline, relating the force exerted on the

body to the filament velocity, is obtained. The equation is

asymptotically accurate to  , where the slenderness parameter , where the slenderness parameter  is the ratio between the

radius and the length of the filament. is the ratio between the

radius and the length of the filament.

An equation for the field velocity in any point away from the

filament is also obtained, to the same accuracy in  . Using this formula, and

the linearity of the Stokes equation, the contributions from all

other filaments can be added to the equation for one single

filament. We obtain a set of equations for the time evolution of

all the filament coordinate functions, that describes the fully

coupled problem, i.e. it contains both the fluid-filament

interactions as well as the filament-filament interactions, as

mediated by the fluid. . Using this formula, and

the linearity of the Stokes equation, the contributions from all

other filaments can be added to the equation for one single

filament. We obtain a set of equations for the time evolution of

all the filament coordinate functions, that describes the fully

coupled problem, i.e. it contains both the fluid-filament

interactions as well as the filament-filament interactions, as

mediated by the fluid.

The filaments we are considering are inextensible and elastic.

Replacing the force in the integral equation by an explicit

expression based on the shape of the filament, using

Euler-Bernoulli elasticity, yields a time-dependent integral

equation for the motion of the filament centerline. This equation

will include the filament tension, for which an equation can be

derived by using the condition of inextensibility of the filament.

The evolution of the system therefore, in each time step, requires

the solution of an auxiliary integro-differential equation for the

filament tension.

The resulting time-dependent equation suffers from an

instability at small, unphysical length scales. The numerical

method is therefore based on a modified integral equation that

removes this instability.

In our numerical algorithm, the filament centerlines are

parameterized by arclength, and discretized uniformly. All

derivatives are computed using second-order divided differences.

Special quadrature rules have been developed to compute the

necessary integrals. A second-order time-stepping scheme is used,

with implicit treatment of high derivatives. A product integration

method is applied to evaluate the integrals in the integral

operators.

We place our filaments in a shear flow. In the

non-dimensionalized equations, there are two physical parameters.

One is  , the

radius over length ratio, and the other one is , the

radius over length ratio, and the other one is , which relates the

characteristic fluid drag to the filament elasticity. , which relates the

characteristic fluid drag to the filament elasticity.

If one single straight filament is inserted in a plane shear

flow at some angle to the x-axis, it will simply rotate around its

center of mass. If we introduce a small perturbation to the

filament, so that it is not exactly straight, there are two

possible scenarios. Either, this perturbation will disappear with

time, and the filament will stay straight. However, if the filament

is under compression for some time, and if the value of  is large enough, then a so

called buckling occurs. As we increase is large enough, then a so

called buckling occurs. As we increase  , this buckling becomes more

pronounced. , this buckling becomes more

pronounced.

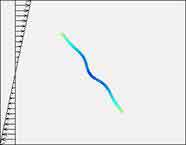

We present short animations that show the fundamentals for this

buckling, for  , for

three different values of , for

three different values of  and and  .

In these animations, the filament has been colored with the line

tension. The line tension changes from negative to positive, as the

filament goes from being under compression to being under

extension. We can note that if the initial configuration x

is reflected to -x, it will evolve under the symmetry .

In these animations, the filament has been colored with the line

tension. The line tension changes from negative to positive, as the

filament goes from being under compression to being under

extension. We can note that if the initial configuration x

is reflected to -x, it will evolve under the symmetry  . Hence, if we change the

sign of the perturbation, the filament will buckle in the other

direction. . Hence, if we change the

sign of the perturbation, the filament will buckle in the other

direction.

Each movie is approx. 700KBytes

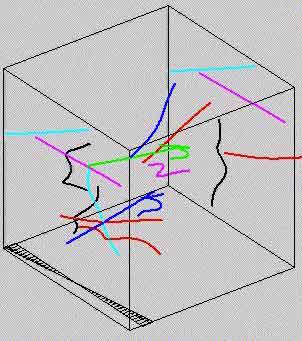

Next animation is one of 15 interacting filaments, inserted into

a oscillating background shear flow, . We impose periodic boundary conditions in the

streamwise (x) direction. The animation shows one period in

time. . We impose periodic boundary conditions in the

streamwise (x) direction. The animation shows one period in

time.

Movie is approx. 2Mbytes

The parameters are and and  . We use

N=100 points to discretize each filament, and a time step . We use

N=100 points to discretize each filament, and a time step  =0.0128. =0.0128.

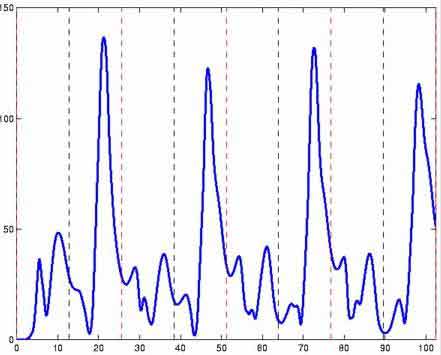

When the filaments buckle, they store elastic energy, that will

later be released back to the system. In the figure we plot total

elastic energy plotted versus time t. The period for the

oscillating shear flow is 25.6, and the dashed lines marks each

half period, i.e. the points in time when the background flow

changes direction.

Interesting phenomena to study for suspensions are filament

orientation, suspension viscosity as a function of volume fraction

and flexibility of the fibers, and normal stress differences.

Already for one single filament in the plane, we find that as it

buckles, integrated over a full rotation, it yields a positive

first normal stress, which is not the case if buckling does not

occur. The anti-symmetric configuration  yields identical normal

stresses, and hence there is no configuration that can yield a

negative normal stress contribution, cancelling that positive

contribution. yields identical normal

stresses, and hence there is no configuration that can yield a

negative normal stress contribution, cancelling that positive

contribution.

|